Photos by George Black

This story originally appeared on the OnEarth website.

Down in the hole that used to be Rana Plaza, the crushed remains of half a dozen cars were still waiting for removal, and next to them was a broken mannequin. She was lying on her back. She wore a pair of tight purple knee-length pants, but she was naked above the waist. Her torso had been severed in a neat diagonal below the right breast, but her head was intact. She had ivory skin, a pink rosebud mouth, ash-blonde hair brushed straight back off her forehead, and piercing blue eyes that stared up without expression at the sky.

More than 1,100 Bangladeshi garment workers died here in April, almost half as many as died in the World Trade Center. Yet the first thing that hit me about Rana Plaza was how small it was. The footprint of the building was not much larger than a basketball court. The site of the Twin Towers covered 16 acres. All that remained of Rana Plaza now was this shallow pit, a few inches deep in muddy water from the pre-monsoon rains, ringed by mountains of rubble and twisted rebar and damp piles of half-sewn clothing and bolts of brightly colored cloth.

The building next door was still under construction. Its façade had been stuck on, a thin veneer of blue reflective glass, but the interior was just a raw skeleton of brick and mortar walls and concrete pillars. It was hard not to wonder whether it would be any safer from collapse than Rana Plaza had been, whether its construction had involved the same unholy collusion between venal developers and corrupt local politicians. I took the unfinished stairway to the top floor and found that the upper levels had suffered a good deal of collateral damage. Huge segments of the roof had bellied downward and were propped up in a tentative way with culms of bamboo. Whole walls had been blown out by the force of the collapse, and papers from the upper floors of Rana Plaza had floated in. Even two months after the disaster, many were still strewn about in the wreckage. There were cards with samples of buttons and zippers, and pattern forms and order books and cutting instructions. Many of these related to contracts with the United Colors of Benetton, headquartered in Treviso, Italy, and were shakily translated from the Italian for workers who couldn’t speak English (regolare bene le tensione delle macchine—”adjuste better the tension machine”).

You could see the mannequin and the pattern books, of course, as a simple parable of the modern world economy, the hidden costs of a global supply chain that keeps us well supplied with cheap consumer goods. Many of the journalists who flocked here after the disaster probed the raw nerve of our moral culpability, although mostly they hewed to the conventional tragedy-in-a-poor-country narrative: evil owner (which he was), innocent victims (which they were), the one miraculous survivor. (There always is one in these stories; at Rana Plaza it was a woman who somehow made it out alive after being trapped in the rubble for 17 days.)

Yet while the image of the broken, blue-eyed mannequin haunted me, I wondered if it really captured the full story behind the catastrophe. It seemed to me that there were deeper meanings to be uncovered. Who were these women? Why had they left their rural homes and flocked to Dhaka, probably the most unlivable, environmentally blighted mega-city in the world? In the end, I found that it wasn’t the mannequin that held the answers, or the Benetton patterns. It was those few inches of rainwater in the pit. For water is the existential curse of Bangladesh, and it is the point of intersection between the two stories that periodically drive this country of 160 million into the headlines: its disaster-plagued garment industry and its extreme vulnerability to climate change.

* * *

The twin garment centers of Savar (where Rana Plaza was located) and nearby Mirpur (the most rapidly growing area of the city) lie on the northwestern outskirts of Dhaka. The capital of Bangladesh today is a city of 15 or 16 million, and that number is swelled each year by more than 400,000 migrants from rural areas. By 2020 the population may reach 20 million. By 2030, it will rise to 25, even 30 million. “That’s when our real nightmare begins,” said Babar Kabir, senior director for disaster, environment, and climate change at BRAC, a giant NGO that occupies a 21-story building in Dhaka. “Will the city even survive?” Like many educated Bangladeshis, Kabir affects a kind of droll gallows humor in describing his country’s calamities. But when he posed this question, I think he was entirely serious. The whole city, he seemed to imply, was like Rana Plaza on an epic scale, a rickety, jerrybuilt structure that might eventually collapse.

A growing number of the new rural migrants are young women, mainly poor and uneducated, drawn to Dhaka by the promise of work in the apparel industry, which now employs more than three and a half million people, mostly in and around the capital. They will work for ten hours a day, six days a week, and often more, starting at the minimum wage of 3,000 taka a month—about $37. But that’s only one way to look at the industry. Another is that it accounts for fully 80 percent of Bangladesh’s export earnings. Growing at 12 percent a year, it is the single factor driving the country’s progression from one of the world’s poorest to what J. P. Morgan calls one of the “Frontier Five” emerging economies, along with Kazakhstan, Kenya, Nigeria, and Vietnam. For European and US buyers, Bangladesh is the new China—because rising wage levels and labor shortages are pricing China’s garment factories steadily out of the market. Newly prosperous Chinese are more likely these days to wear Benetton clothes than to sew them.

For migrants from rural Bangladesh, then, jobs in the apparel industry, no matter how unsafe and poorly paid, are the pull. But what is the push?

In essence, it’s water. Some Bangladeshis have too much of it, and others, paradoxically, too little. But for almost everyone, there is too little of the right kind—the kind you need for your household needs, for farming, for keeping your children healthy. “We are a country of rivers, but we have no water to drink,” said Shirin Akhter, the founder of an NGO called Karmojibi Nari (Working Women) and a veteran advocate for the garment workers.

Two of Asia’s great rivers cut through the western half of Bangladesh, and their combined floodplains are never more than a few feet above sea level. The Ganges—which Bangladeshis call the Padma—snakes its way into the country across the Indian border. The Brahmaputra pours down from the mountains of Tibet. A little way west of Dhaka, the two rivers merge to form the Meghna. By the time it reaches the Indian Ocean and straggles off into an ever-shifting archipelago of low-lying islands and sandbanks, the Meghna is 20 miles wide. Stretching westward to the Indian border and beyond are the “100 Mouths of the Ganges,” a vast delta of smaller rivers and channels and the labyrinthine mangrove forests of the Sundarbans, last redoubt of the Bengal tiger. And this whole area lies squarely in the path of the ferocious cyclones that gather their strength from the warming waters of the Bay of Bengal.

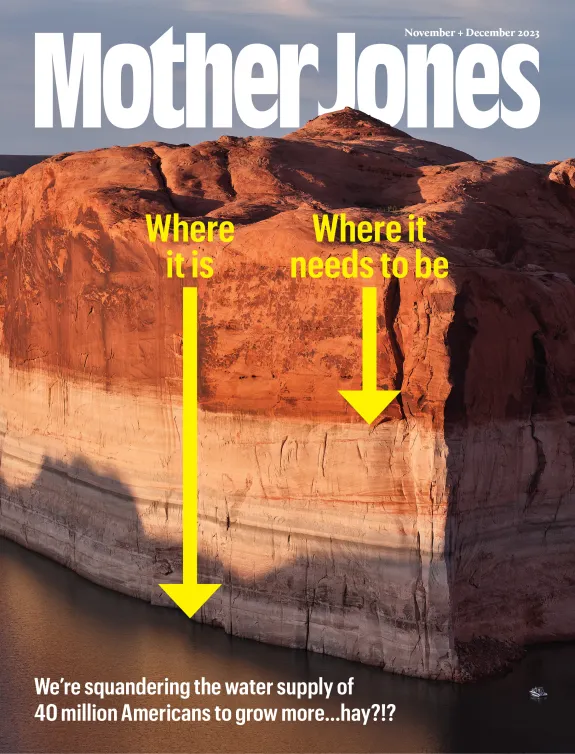

The monsoon, which finally broke in full force three days after my visit to Rana Plaza, would subject Bangladesh to its customary annual floods. Rivers would burst their banks, inundating farmland. Entire sections of riverbank would succumb to the force of the current, dumping fields and homes into the water. On occasion, the Ganges has even been known to swallow up entire villages. Huge and laden with silt, the rivers would continue to carve out new channels and alter their course. As one illustration of this, the river that curls around the western edge of Dhaka is called the Buriganga, or “old Ganga.” The reason is that several centuries ago it was connected to the Ganges. Today the big river is 40 miles away.

* * *

It is from these sodden places that the garment workers and other migrants flock to Dhaka. The easy shorthand is to call them “climate refugees.” That term had recently come into vogue when I last visited Bangladesh five years ago, after a monstrous cyclone named Sidr battered the country and scientists began to run scary projections of the numbers of people who would eventually be driven from their homes by sea-level rise and ever-fiercer storms. Now it’s understood that “climate refugees” is a crude oversimplification. Better, I was told by Sarat Dash, the chief of mission in Bangladesh for the International Organization for Migration, to speak of “environmental migrants,” because that captures the full complexity of their situation, embracing the interplay of factors—some dramatic, others more subtle—that drive them from their homes.

Yes, Dash agreed, the ocean was still the headline-grabber. “If there’s a one-meter rise in the sea level, that will lead to the loss of 18 percent of our land area,” he said. “That means 11 percent of our population, and that means 17 million people.” And people, as Babar Kabir had told me a couple of days earlier, “are not so stupid as to just sit there and die.”

Yet there may be a whole tapestry of other reasons behind any given family’s decision to move. Migration specialists distinguish “slow-onset” environmental change from change that is “sudden” or “extreme.” A cyclone or a storm surge is extreme, but unless it wipes out a family’s livelihood completely, it may provoke only short-term migration to a nearby town or village, followed by return home when conditions permit. Dash calls this “circular migration.” While less visibly traumatic, it’s the slow-onset change that is more pernicious.

In the coastal southwest, it may be the steady seep of salt into farm fields and drinking wells as a result of the encroaching ocean and the diminished flow of rivers in the dry months, which reduces their ability to flush the salt back out to sea. In the early stages, a farmer will begin to notice that he is harvesting less rice, a fisherman that his catch is smaller, a pastoralist that there is less grazing land. Steadily things grow worse until he runs out of ways to adapt. Perhaps the worst affected area is Barisal district, along the lower reaches of the Meghna, which accounts for almost a quarter of all migrants to Dhaka, including, as I would discover, a large number of garment workers.

In the drier northwest, north of the Ganges, the problem is often a rapidly declining water table and recurrent crop failures. “With population growth, the extraction of groundwater and surface water is getting pretty enormous,” Kabir said, “and with climate change it becomes a semi-permanent problem.” When people leave in response to slow-onset changes like these, they tend to leave for good.

* * *

And so they come to Dhaka, a thousand or more every day, even as the experts debate whether their movement is a legitimate adaptation to climate change or proof that the effort to help people adapt to harsher conditions has failed. This may sound like an arcane distinction, but in fact it’s hugely important, because billions of dollars—in government budgets and international aid—are at stake. Where should the money go? To improve conditions in climate-threatened rural areas so that people can stay in their homes? Or to invest more in the cities, accepting that the battle against forced migration is lost? Or both? Opinions are deeply split.

The flight from sea-level rise, flooding, storms, and the loss of farmland has a powerful cascade effect on the city. Once they arrive in Dhaka, migrants find that they face a new version of the very thing they were trying to escape, trading one form of water scarcity and pollution for another, and aggravating the problem by the simple fact of their own presence. Generally it’s the main breadwinner who comes first, his family following in stages as he gains a foothold in the city. As likely as not he’ll start off as a pavement-dweller. Tracking opportunities by word of mouth, he may find work as a day laborer or a garbage picker, a seller of tannery scraps or a brick-breaker or a security guard, sitting all night on a plastic chair in the dark outside a parking garage or an ATM booth. Many will join the ranks of rickshaw-pullers, earning 230 taka a day ($3) pumping the pedals of one of the 600,000 or more machines that careen around Dhaka’s overcrowded streets, many of them decorated with bright, wistful fantasies of a rural world filled with blue lakes, brightly painted cottages, tropical flowers, swans and peacocks, deer and tigers.

The migrant will find a place to live in a basti, one of Dhaka’s hundreds of slum areas, some no more than a precarious straggle of bamboo stilt houses along a polluted canal, others virtual townships of 100,000 or more, with their own complex internal economy and social order. He’ll sleep in a room that measures six feet by eight, perhaps sharing his bed with other men working rotating shifts, paying his monthly 700 taka to the local slumlord. “It’s like the Godfather or Al Capone,” Kabir said. “There’s a whole invisible pyramid of lieutenants and sublieutenants and rent collectors. And if you fall behind on payments, you’ll get a visit from the mastaan, the muscleman.” As for potable water, unless some kindly NGO has installed a tap, the migrant may have nowhere to turn but to the “gray business” that controls its sale in the slums, often paying more than 50 times as much for a liter of potable water as middle-class people who get it from their faucets.

As he puts down fragile roots, the man’s family will join him, sometimes one by one, sometimes all at once, the sons following his pursuit of menial jobs and the women bound for domestic service, manual labor, or the apparel industry. But increasingly, the women who flock to the garment factories also come alone, or to join a sibling or a friend from the same village. “These are often adventurous young women,” Kabir told me, “and they need to find an honest middleman, because there are plenty of others out there who will take them for a ride, sell them into brothels or traffic them across the border into commercial sex work in India.” Sometimes women will even be drawn into Bangladesh’s booming black market in human organs, cajoled into selling a kidney for the equivalent of a year of minimum wages. Once a young woman finds a job, kinship is the engine that drives much of the subsequent recruitment: she does well, she recommends her sister, who then calls a cousin, and so on until a half-dozen members of the family may be working in the factories of Savar and Mirpur.

The less fortunate may find their way to the sweatshops that serve the domestic market, where I met 11- and 12-year-old boys and girls working 80-hour weeks to keep up with demand. (We forget, with all the talk of the Benettons and Gaps and WalMarts, that 160 million Bangladeshis also need a steady supply of cheap saris and lungis, pants and T-shirts.) Many of these miniature factories are strung out along the west bank of the Buriganga, which runs sluggish and foul, biologically dead, almost black in color, coated with an iridescent sheen of spilled oil. In the whole of Bangladesh there is just a single sewage treatment plant; located on the southern outskirts of Dhaka, it can deal with less than 10 percent of the sewage generated in the city. The rest, 1,100 tons of untreated human waste each day, goes straight into the rivers, ponds, canals, and gutters.

Dhaka’s poorest bastis occupy the lowest and most flood-prone sections of the city, inundated during each monsoon system with sewage-tainted water that brings disease in its wake. Overall, rainfall in Bangladesh has declined as the climate changes, but the rains are now more concentrated in the peak months of the monsoon season, more than doubling in volume in August alone over the past 20 years. “The city’s drainage system is equipped to deal with 10 millimeters of rain [less than half an inch],” said Iftekhar Mahmud, a senior reporter for Prothom Alo, the leading Bangla-language newspaper, who has reputedly written more on climate change than any other journalist in the country. “But we often get 10 or 20 times that much in a single day.” To make matters worse, the natural drainage areas that are critical in buffering the monsoon floods have steadily been encroached upon as land grabbers pump them dry to put up new housing, much of it illegal. Bangladeshis call this sandfill; one new development I saw on drained land next to the Buriganga covered nearly 400 acres, more than half a square mile.

* * *

If the horrors of Rana Plaza made us think about the industry behind our clothing labels, the image it conjured was probably one of rows of women bent over sewing machines. But this is only the top layer of the apparel pyramid. Beneath it are thousands of other, less visible workplaces, without which there is nothing to sew in the first place. No cloth, woven, colored, and patterned; no leather to be fashioned into belts, shoes, and sneakers, or the decorative trim on blue jeans. And the impact of these hidden links in the global supply chain on Bangladesh’s scarce supply of clean water is hard to grasp until you see it up close.

I went out one hot, humid morning to a neighborhood called Hazaribagh, which is home to virtually all of Bangladesh’s tanneries and the single worst source of pollution of the Buriganga. I stopped outside the Salma Leather Factory and chatted with a woman who was laying out rough squares of cowhide to dry on a garbage-strewn patch of waste ground. I wasn’t surprised when she told me that like many people in Hazaribagh, she was originally from Barisal District, a farming village near the mouth of the Meghna. Two of her brothers had found work in the garment factories, she said. Nearby, a grizzled older man, helped by a girl of 10 or 11, was trampling scraps of dried meat that had been scraped off the hides, reducing them to powdered fishmeal or chicken feed. Two other men squatted at the edge of a garbage dump, surrounded by piles of old shoes, painstakingly separating out the leather from the rubber and plastic, which they said would be melted down to make new soles. Nothing goes to waste in Dhaka—nothing, that is, except water.

I asked if I could look around inside the factory. The foreman, whose name was Bahar, a paunchy, barrel-chested man with a bushy beard, said that would be fine. Business was slow right now; Hazaribagh was waiting for the Shab-e-Barat, the “night of deliverance,” at the end of June, when there would be a mass slaughter of animals. Tons of meat for the feasting; tons of hides for the tanneries.

What they produced here, he said, was “wet blue,” the first stage of leather manufacturing. Later the hides would be shipped off to a separate plant to be turned into “crust leather,” and then to a third factory for finishing. “Wet blue” is the dirtiest and most dangerous part of the industry. The conditions in the windowless, unventilated shed would have shocked Engels or Dickens, and they lived in an age before the invention of synthetic chemicals. Bahar showed me how the hides are softened for 24 hours in huge, rotating wooden drums, where pumped groundwater is mixed with lime and sodium sulfide to remove the last of the hair and flesh. After that comes a whole suite of other toxic chemicals and additives (a recent report on Hazaribagh by Human Rights Watch listed about 30). I tried not to think too hard about the belt and shoes I was wearing.

The most hazardous of the chemicals, however, is chromium sulfate, which gives the wet hides their distinctive gray-blue color. Bangladesh’s tanneries use 3,000 metric tons of the stuff each year, and those who handle it should always wear protective gloves, safety goggles, and a face mask. Perhaps it is unnecessary to say that none of these was in evidence here. Factory inspectors never visit Hazaribagh; the government itself acknowledges that, “There is no monitoring and no enforcement in Hazaribagh.” There are regular vows to relocate the tanneries to Savar, one of the two main garment districts, consolidating them into fewer, larger, and more modern facilities that would share a central effluent treatment plant. The Savar tannery complex was first suggested 20 years ago. In 2002, a deadline was set for the move: the end of 2005. Wait, make that 2006. No, let’s say 2010. If the Hazaribagh tanneries were not gone by then, the High Court of Bangladesh ruled, they would be closed down. Three years later, they’re still there. The move to Savar is now set for 2015; or perhaps 2017; or perhaps never.

The air in the Salma Leather Factory was rank with hydrogen sulfide, sulfur dioxide, and ammonia. A noxious blue slime coated the floor and slithered into a drain hole. On the other side of the wall, laden with heavy metals, animal flesh, fat, and dissolved hair, the slime would make its way into the gutters and alleyways of the neighboring basti, and thence to a series of drainage channels and small streams before finally being decanted into the Buriganga, half a mile away. Actually, that is an over-simplification, because until it was sluiced along on its journey by the monsoon rains, which were due any day, much of the effluent sat in a nearby stagnant pond that was half-choked with water hyacinths. Naked children were frolicking in the water, and a woman from the basti was beating her laundry on a rock.

* * *

Next day, a friend drove me out beyond the city limits to the northeast to see the dyeworks and the textile mills that produce the raw material for Dhaka’s sewing machines. The monsoon had finally broken, and the first fierce showers were hammering down on the fields, which were still waterlogged more than six months after the end of last year’s rains. For mile upon mile these fields had been staked out for drainage and development by real estate companies, whose signs were planted at intervals in the knee-deep water. This is where Dhaka would grow in the future to accommodate the 25 million, the 30 million that Babar Kabir feared would push the city to the tipping point, threatening its very survival.

The dyeworks that supply the domestic sweatshops along the Buriganga with lower quality cloth, not suitable for the export market, had me thinking of Dickens again. Whole villages, rabbit warrens of poor homes divided by narrow, muddy lanes, and vibrating to the clatter of cast-iron looms that looked as if they dated back to the Industrial Revolution, were dedicated to the business of weaving and dyeing. The highway was lined with lengths of dyed cloth, orange, yellow, red, purple, green, and blue, hung out on string to dry like some roadside version of Christo’s Central Park project, The Gates. In their earth yards, men and boys were sloshing more cloth around in zinc bathtubs, up to their armpits in dye, hands and wrists stained permanently indigo and crimson. One man said he scrubbed his arms every night with scouring powder and bleach, but it didn’t make much difference. He upended his tub and poured some of the liquid into a drain to run off into a nearby stream. “Don’t worry,” he grinned, “this is good water. It doesn’t harm you.”

Farther east was Bangladesh’s main concentration of textile mills, strung out along a 25-mile stretch of highway near the town of Narsingdi. We stopped at B.L. Apparels (“100% Export Oriented and Composite Industries”). This was a much larger enterprise, a solid cement building occupying several floors. The word composite meant that it handled everything from weaving and dyeing to the silkscreen printing of finished fabric, producing saris as well as polo shirts, the latter destined mainly for markets in Australia and New Zealand. At first, the visit did nothing to lift my gloom. Standing pools of gray caustic liquid had gathered under the rollers in the washing and pressing area. There was a pervasive stench of hydrochloric acid.

But this wasn’t the whole story, I discovered, as the factory manager showed off some of the recent innovations to the mill. When a country begins to develop its garment industry, most of the raw material has to be imported. But as it grows, the domestic textile-milling sector will rapidly expand to serve it, with all stages of production housed under one roof. That’s what happened in China, and it’s happening now in Bangladesh.

“There are about 100 larger textile mills in this area now,” the manager said. “Within 10 years there will be hundreds more, and they’ll be much bigger. This mill was very small when I came here 10 years ago. It had only 25 or 30 workers. Now there are close to 800.”

He took me upstairs and along a narrow catwalk to see the pride of B.L. Apparels: its effluent treatment plant. The water that’s used in the mill is recycled, filtered, and pumped up to a series of diamond-shaped rooftop tanks, where it’s treated with powdered lime and ferrosulfate until its pH level is within government-set limits, only slightly more acidic than the surrounding groundwater. Then it’s released into a canal that flows into a nearby river.

“This is all new,” the manager said. “The rules came in about two years ago. About 10 percent of the mills have completed their treatment plants, and the other 90 percent are under construction. They’re financed by government loans, and you can no longer get a license to open a new plant without one.” You had to be on your toes, he said, for government inspectors show up unannounced about once a month for spot checks.

The rule of thumb seemed to be that bigger was better. The small tanneries and local dyeworks operated in the regulatory darkness, flushing their vile effluent into the waterways without restriction. To judge from the textile mills of Narsingdi, the more the industry was dedicated to the export market, the larger the factories, the more they would be scrutinized, the more likely it was that they would be forced to clean up their act. Rana Plaza had exposed Western buyers like Benetton as complicit in the dark side of Bangladesh’s apparel industry. But here was the paradox: that those same companies, by deepening their engagement, might also be its best hope for reform. The most important question of all, it seemed to me, was what the garment workers themselves thought of this, so I went to Savar and Mirpur to ask them.

* * *

There is a surprising lack of hard demographic data about the women in the garment industry: the companies may know the basic facts (name, age, place of origin), but they see no compelling need to share them; the government doesn’t seem interested; and the academics, NGOs, and advocacy groups don’t have the resources to do a systematic analysis. Yet some clear patterns emerged from my conversations.

Sarat Dash of the International Organization for Migration had talked to me earlier about the complexity of environmental migration, and the time I spent in Savar and Mirpur began to fill in some of the granular detail. I picked up one early clue from Mahmudul Sumon, an anthropologist at Jahangirnagar University in Savar, who heads a team studying Bangladesh’s last-but-one disaster, the fire at Tazreen Garments last November that killed at least 112 people (that was the official estimate: Sumon says the true figure was 124). Eighty percent were women, the majority were in their twenties; a good number were under 18. But the most striking finding, Sumon said, was that a high percentage of those who died had migrated to Dhaka from a single small district in northwestern Bangladesh, in an area notable for its falling water table and frequent crop failures.

Later, in Mirpur, I found that a large number of the women were from the southwest, not the northwest, forced from their homes by cyclones, floods, and salinated farmland. Shirin Akhter thought the different demographics had a lot to do with transportation routes: buses from the southwest arrived at a big depot near Mirpur; those from the northwest stopped first in Savar. She said she had watched migration trends closely since founding her advocacy group, Karmojibi Nari, back in 1991, when women first began entering the labor market in large numbers. They gave many reasons: rural poverty, lack of educational opportunity, job prospects in the city. But in recent years, and especially after Cyclone Sidr in 2007, they increasingly cited environmental stressors. “They don’t necessarily use those words,” Akhter said. “But what they do say clearly is that they can’t go back because they’ve lost their homes or their land to the water.”

I met a number of migrants from the northwest in a sprawling Savar neighborhood called Jamgora. It’s one of Dhaka’s largest slums, home to more than 100,000 people, and it turned out to be quite different from the others I’d visited. Some women may live in the bamboo, tin, and palm-frond huts of the bastis when they first arrive and are making minimum wage, but in time, as their earnings rise closer to the average of about 6,000 taka ($75) a month, they will gravitate to places like Jamgora.

The development is dominated by rows of grim concrete tenements, and the rooms, often shared by several people, are dark and cheerless, with heavy metal doors and windows secured by padlocks against theft. Yet the women who live here are not the poorest of the poor. Rents in Jamgora are two or three times higher than in the bastis, and water and electricity are included. In one room, two young women in their late teens were sprawled on the bed watching a soap opera. One of them, speaking in a shy whisper, said she was from a village in an arid northwestern district, near the town of Bogra. A young man wandered over to join us. He said he was from the same area. The family’s crops had failed once too often; now his mother, a brother, and three sisters were all working the sewing machines.

Despite their arduous working conditions, with low wages, no sick leave, little job security, frequent sexual harassment, not even the right to ask for a toilet break—not to mention the constant fear of another disaster like Tazreen or Rana Plaza—women in places like Jamgora have begun to achieve a modest degree of upward mobility and independence. Most are still unmarried, and although they may sometimes yearn to return to their villages, they have broken free of many of the restrictive taboos of village life. Remaining at home, they might have faced an early marriage, arranged by a father desperate to keep down the cost of his daughter’s dowry, which will increase as she gets older. But here they can chat with friends on their cell phones, go out at night if they’re not too tired, perhaps dare to put on a little lipstick. If they’re hard-pressed to pay the rent, I was told, some will even split the cost with a (usually Platonic) male roommate.

* * *

I spent the following evening with a group of about a dozen women in Mirpur. They gathered in a circle on the floor of a local office of Karmojibi Nari and recounted the stories of their migration. All but one were from the southwest coastal region, nine of them from Barisal, the area worst afflicted by climate change and extreme weather. The stories varied from one woman to the next, but water was their common thread.

One young woman had come to Dhaka from the edge of the Sundarbans, the vast coastal mangrove forest, because a tiger, driven from its customary habitat as the land grew saltier and the availability of prey diminished, was menacing her village. Another got a call on her mobile from a neighbor, warning that the riverbank by her home was slipping into the water; by the time she got there, her house, garden, and trees had all vanished. Other stories were a more nuanced mix of “extreme” and “slow onset” changes. Nargis, from a village near the mouth of the Meghna, had left after Cyclone Sidr with four siblings, all of whom now worked in the garment industry. But her parents had insisted on staying behind, and the remittances from their children had helped them rebuild their small farm. Jesmin, also from southern Barisal, had come to the city as a teenager with her brother after their father died of leukemia. Another brother followed, and soon all three were working in the garment industry. A decade later, after Sidr struck, village life became so precarious that Jesmin’s mother and two remaining siblings concluded they could no longer survive in Barisal, and they headed for the city too.

Jesmin was 30 now. She wore an elegant red sari and a tiny gold nose stud. She had high, sculpted cheekbones and dark, deep-set eyes, and while some of the other women stared shyly at the ground and told their stories in almost inaudible monosyllables, Jesmin had a calm and direct gaze, a poise, a natural charisma that marked her out right away as a future leader. She spoke eloquently of the hardships the women faced, the nostalgia they sometimes felt for their villages, their resentment of official indifference. But when the conversation turned to Rana Plaza, and the well-intentioned reluctance of western consumers to buy clothes from a country that permitted such things to happen, she began to laugh, and soon most of the women in the room were laughing and shaking their heads. It was as if I’d told the sickest joke in the world.

“What our girls are saying is don’t boycott us,” Shirin Akhter said later. “Just give us a safe workplace.”

It’s the greatest of ironies: while shoppers are tortured by conscience, while the Walt Disney Company pulls out to protect its “brand integrity,” no one in Bangladesh—no one—wants the apparel companies to leave. The government needs the export earnings; the economists see the industry as the key to Bangladesh’s emergence as the next Asian tiger; the factory owners want the profits; those concerned with corporate social responsibility warn that if western garment buyers pull out, Chinese and Indian buyers will move in (and no one should expect them to care as much about effluent treatment plants and safe water); and the women and their advocates want the jobs—together with the labor rights, fair wages, and healthy working and living conditions that should go with them.

When the laughter in the room finally subsided, Jesmin looked me straight in the eye and said with a smile, “If you stopped buying the clothes we make, what do you think we would do? We’d die.”