Simulation of a metal dust flash fire inside the Hoeganaes plant in March 2011 that injured one worker.US Chemical Safety Board

Small fires were a part of the job at the Hoeganaes Corporation metal powder plant in Gallatin, 30 miles northeast of Nashville. By early 2011, some workers later told investigators, they had become practiced in beating down the flames with gloved hands or a fire extinguisher.

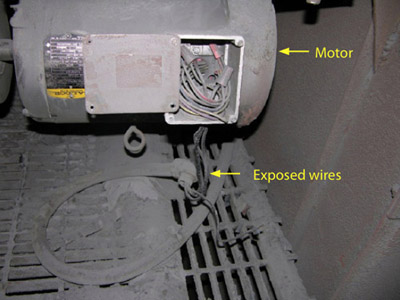

The company’s own product—a fine iron powder sold to makers of car parts—fueled the fires. Sometimes, powder leaked from equipment and coated ledges and rafters. Under the right conditions, it smoldered. Wiley Sherburne, a 42-year-old plant electrician, sometimes told his wife how this dust piled up everywhere, she recalled. On quieter weekend shifts, he said he could hear the telltale popping sound of dust sparking when it touched live electricity.

In the early morning of January 31, 2011, Sherburne was called to check out a malfunctioning bucket elevator. Near his feet, electrical wires lay exposed. When the machine restarted, the jolt knocked dust into the air. A spark—likely from the exposed wires, investigators later concluded—turned the dust cloud into a ball of flame that engulfed Sherburne and a coworker.

“He’s burned over 95 percent of his body,” doctors told Sherburne’s wife, Chris, when she arrived at the Vanderbilt University Medical Center’s burn unit. “He’s not going to live.” Wiley died two days later.

He wasn’t the last Hoeganaes worker to perish in a dust fire. Another blaze struck in March, then a third in May. In all, five workers died in accidents that shook this small community. Each man left behind a wife and children. One had four children under 11. Another had become a grandfather the day before the explosion.

Each of the blazes involved combustible dust, a little-noticed danger that has killed or injured nearly 1,000 workers across the country during the past three decades. The fuel has varied—wood, nylon, coal, flour, plastic, sugar—but the effects have been similarly devastating. Since 1980, more than 450 accidents involving dust have killed nearly 130 workers and injured another 800-plus, according to a Center for Public Integrity analysis of data compiled by the federal Occupational Safety and Health Administration and the US Chemical Safety Board. Yet a push to issue a rule protecting workers from the danger has stalled in the face of bureaucratic hurdles, industry pushback, and political calculations.

Aftermath of a 2008 dust explosion that killed 14 people at an Imperial Sugar refinery in Georgia US Chemical Safety Board

Aftermath of a 2008 dust explosion that killed 14 people at an Imperial Sugar refinery in Georgia US Chemical Safety Board

OSHA, in a statement, said it must “make difficult decisions as to how to best allocate the agency’s limited rulemaking resources.” While addressing dangers like combustible dust and dangerous substances breathed by workers are important, the agency said, it “has placed a great deal of emphasis on broad rulemaking efforts that have the potential to result in fundamental changes safety and health in the workplace.”

Representatives for Hoeganaes refused interview requests. In legal filings, the company has denied violating safety standards at the Tennessee plant where Wiley Sherburne died.

“All of a sudden one day—boom”

A dust fire is, in a sense, the result of a perfect storm. The powder has to form a cloud in a confined area and touch an ignition source, such as a spark, flame, or overheated pipe. Often, workers don’t know that the dust lurking on flat surfaces could, when dispersed in a cloud, fuel a violent explosion. But experts, worker safety advocates and government officials have been sounding alarms for years.

“It goes along for years with the dust building up, building up, and everything’s fine, nobody’s harmed, nobody thinks anything about it,” said Sandra Bennett, an official at the Tennessee Occupational Safety and Health Administration, which investigated the Hoeganaes accidents. “All of a sudden one day—boom.”

Standards to address the danger have existed for more than 85 years, but following them is voluntary for many plants. Where they are mandatory, enforcement is so haphazard that the association that sets the standards believes this policing duty should be placed in OSHA’s hands. The agency seems to agree. In 2009, OSHA announced it was starting to work on a rule to address combustible dust. But making new rules is a difficult process—costly for industry, politically tough for agencies—and three years later, the dust rule is still stuck in its early stages.

Top agency officials refused to discuss the rule’s status. In a statement, OSHA said, “Prevention of worker injuries and fatalities from combustible dust remains a priority for the agency.” But, the statement said, developing the rule is “very complex” and “could affect a wide variety of industries and workplace conditions. As a result it has been moved to long-term action to give the agency time to develop the analyses needed to support a cost-effective rule.”

News of OSHA’s decision to delay the rule reached Chris Sherburne at the end of January, around the first anniversary of her husband’s death. “I just couldn’t believe it,” she said. “You put it on the back burner and that’s where it’s going to stay.”

Her frustration is shared by victims’ families who have seen other health and safety rules similarly stalled, shelved, or eviscerated. Whether it’s combustible wood dust at a sawmill, disease-inducing beryllium at an aluminum smelter, or lung-wrecking silica at an iron foundry, OSHA standards allow some conditions that even the government’s own scientists consider unsafe.

OSHA, in a statement, said it is “committed to protecting workers” but that “numerous steps in the regulatory process mean OSHA cannot issue standards as quickly as it would like.”

Fine metal dust collected at the Hoeganaes plant (penny shown for scale) US Chemical Safety Board

Fine metal dust collected at the Hoeganaes plant (penny shown for scale) US Chemical Safety Board

Metal dust near exposed wiring on an elevator motor near the site of the fatal January 2011 explosion in the Hoeganaes plant US Chemical Safety Board

Metal dust near exposed wiring on an elevator motor near the site of the fatal January 2011 explosion in the Hoeganaes plant US Chemical Safety Board

“Close calls for something that could kill somebody”

Documented dust explosions have been killing workers since at least the late 1800s, and technical publications discussing the hazard date to the early 20th century.

The Chemical Safety Board (CSB), an independent federal agency, has examined a handful of major dust accidents and identified disturbing trends. The board, however, can’t issue or enforce rules. And records show that the plants involved in the catastrophic accidents the board investigated also had a history of smaller dust fires.

“You have to consider all those fires as close calls for something that could kill somebody,” the board’s chairman, Rafael Moure-Eraso, said in an interview. “Hoeganaes is precisely the case in point.”

At the Gallatin plant, periodic small dust fires ignited in certain areas. Employees told state inspectors they put out blazes more than once a month. Because the fires had done little damage, workers had come to accept them as part of the job, investigators found. That changed the January day a dust cloud ignited and fatally burned Sherburne and Wayne Corley.

Two months later, a worker accidentally knocked loose dust that had collected on a furnace and was engulfed in flames. He leaped off a ladder to safety and survived. Then, on May 27, sparks triggered an explosion of hydrogen gas leaking from a pipe. The blast shook dust loose from the rafters, and some of it ignited as it rained down on workers. “There was so much dust in the air that you could only see the areas where it was burning,” one employee told investigators. Three workers died, and two more were injured.

Hoeganaes was no stranger to deadly dust. The May accident in particular bore “striking similarities” to one that occurred in 1992 at the company’s plant in Riverton, New Jersey, said the CSB’s lead investigator, Johnnie Banks.

Twenty years later, Jeffrey Richardson remembers that accident well. A hydrogen explosion shook the building, and burning dust fell from the rafters. Richardson recalls it covering him as he struggled to find an escape route. “I could hear it sizzling and cracking,” he said.

He was left with third-degree burns covering 97 percent of his body. He has one ear and one hand, though it has no fingers. His body is covered with skin grown in a lab; it heals slowly and tears easily. “They said my foot and my eyelids were the only place where I wasn’t burned,” he recalled recently. “I still to this day have a nurse come every day to dress wounds that I still have ongoing.”

The company contested the 10 serious violations OSHA issued for that fire, and the agency cut the fine from $22,500 to $15,300. Hoeganaes is now contesting the 25 serious violations and $122,900 in fines assessed by Tennessee regulators after the 2011 accidents in Gallatin.

Optional standards, lax enforcement

Many plants already are required to follow rules addressing combustible dust—at least in theory.

The National Fire Protection Association (NFPA), a nonprofit group that sets an array of standards and conducts research and training, first issued guidance in the 1920s. Since then, committees of industry officials and experts have updated the association’s combustible dust standards regularly. Many experts praise the standards, and OSHA often points to them as widely recognized practices when trying to issue violations.

But two problems limit the standards’ reach: They are optional in many areas, and, where they apply, enforcement is often lax or nonexistent, experts have found.

Some state and local governments have adopted the NFPA standards as part of their fire codes, while others have chosen the International Fire Code, which has general guidance on combustible dust and references the NFPA codes without explicitly requiring companies to follow them. Even where the rules apply, those charged with enforcing them are typically state or local fire inspectors. Inspections of industrial plants are rare, the CSB has found, and inspectors are often ill equipped to recognize even glaring dust hazards. “The rank-and-file first line of code enforcement is totally ignorant of the problem,” said John Cholin, an engineer who has investigated dust accidents for 30 years.

Simulation of the January 2011 metal dust flash fire that killed Wiley Sherburne in the Hoeganaes plant US Chemical Safety Board

Simulation of the January 2011 metal dust flash fire that killed Wiley Sherburne in the Hoeganaes plant US Chemical Safety Board

In Gallatin, the fire department’s senior inspector visited the Hoeganaes plant in May 2011—after the first two fires but before the third. He noted a list of concerns, including inadequate emergency lighting and the need to keep exit routes clear. He didn’t mention combustible dust. Department inspectors eventually noted significant dust levels this past January and March. Asked if inspectors ever brought up combustible dust with Hoeganaes before last year’s accidents, Fire Chief William Crook said, “If they have, I’m not aware of it.”

The CSB found a similar pattern after accident investigations in Indiana and North Carolina: Fire officials had missed dust problems in inspections before deadly accidents.

Recognizing dangers that could lead to dust fires and explosions also can be a problem for companies and their insurers. In investigations of four dust explosions that killed 28 workers, the CSB found insurers had missed serious dust hazards during audits in each case.

In Gallatin, the insurer, Allianz, did note the potential risks from iron dust in a 2008 audit. Hoeganaes commissioned testing in 2009 and 2010 that showed its dust was combustible. In August 2010, Hoeganaes hired a company to clean up the dust, according to a report by the state inspector examining the January 2011 accident. But, the report notes, “it was apparent that the employer was not ensuring clean up was maintained through good housekeeping practices between these cleanings.” Piles of dust up to four inches thick sat on equipment throughout the plant, the inspector found.

Such breakdowns point to the need for an OSHA standard, which could lead to “broader recognition and the potential for stronger enforcement,” said Guy Colonna, manager of the NFPA division that oversees the association’s combustible dust standards.

Still, enforcement by OSHA isn’t a perfect solution. The CSB’s 2006 study found that OSHA inspectors weren’t adequately trained to recognize dust hazards. In a statement, OSHA said it developed a three-and-a-half-day session to train its inspectors to recognize combustible dust hazards in December 2007. But the agency can get to only a fraction of the plants that may have dust problems.

Jamie Butler was severely burned in the explosion at the Imperial Sugar refinery in 2008. Chris Hamby/iWatch

Jamie Butler was severely burned in the explosion at the Imperial Sugar refinery in 2008. Chris Hamby/iWatch

Since October 2007, OSHA has been targeting plants that may have dust problems through a special enforcement program. During that time, the agency and its state counterparts have conducted more than 2,800 inspections. But, asked for an estimate of the number of plants that meet the criteria for inspection under the program, OSHA said the total was likely “in tens of thousands.”

After the fires in 2011, state regulators drew on a variety of standards in an attempt to cite Hoeganaes. They alleged electrical safety violations, shoddy maintenance of the hydrogen pipe that leaked in May, and an inadequate emergency response plan, for example. They accused the company of allowing dust to build up throughout the plant and failing to train workers on the dangers posed by dust.

Hoeganaes contested every citation. Among the legal arguments the company has raised: State officials are trying to enforce a combustible dust rule that doesn’t exist.

“Past time to issue a standard”

Four years ago, Jamie Butler sat on a curb outside the burning wreckage of the packing building at the Imperial Sugar refinery in Port Wentworth, Georgia, an industrial hub near Savannah. His brother sat beside him. They’d escaped one of the worst dust explosions in US history.

There had been a ball of flame, Butler recalled, and then fire everywhere—on the walls, on machines, in the air. Sugar dust had exploded in a conveyor belt, then triggered blasts throughout the plant. Dust that had built up over the years fueled the explosions and rained down on Butler and his coworkers.

Butler had found a hole that had been blown in the wall and made it, with his brother, to the curb outside. They talked for a minute or two, before emergency responders loaded Butler into one ambulance and his brother into another. “That was the last time I ever saw my brother,” Butler said.

The disaster killed 14 people—including Butler’s brother and uncle, a longtime plant employee—and left dozens burned. Butler, now 29 with three children, remained in a coma for months; he has severe burns on his head, face, legs, and arms. “Since I got burned, I’ll be in the hospital on a regular basis, just sick, throwing up, dehydrated,” he said recently, sitting in his lawyer’s riverfront office. “I don’t sweat how I used to sweat.”

The blast was the type of catastrophe that can spur reform. Congress held a hearing, and then-Illinois Sen. Barack Obama said in a statement, “It is past time to issue a standard to prevent these kinds of accidents.”

Even before Imperial Sugar, the CSB had investigated a series of deadly dust accidents and recommended in 2006 that OSHA issue a rule to protect workers from dust fires and explosions. After investigating the disaster in Port Wentworth, the board again urged OSHA to act.

This time, OSHA appeared to be listening. It launched a special enforcement program targeting companies with unaddressed dust problems. In April 2009, the agency announced it was starting the rule-making process.

“We felt that our efforts had paid off,” CSB chairman Moure-Eraso said recently. “And then we wait and we wait. And there are more accidents; there are more fatalities. And this process continues, and it seems to be never-ending.”

Long rule-making processes have become the norm for OSHA. For the 58 significant standards the agency has issued since 1981, the average time from beginning the process to finalizing the rule was almost eight years, a recent study (PDF) by the Government Accountability Office found.

To issue a significant new rule, federal agencies must navigate a complicated process that includes multiple rounds of review—both internally and at the White House’s budget office—and public comment. But it’s even harder for OSHA, which must show that a proposed rule is both technically and economically feasible for every industry that would be affected. If a rule could affect a significant number of small businesses, OSHA must convene a panel and allow them to raise objections to an unpublished rule draft. And finally, the agency is particularly vulnerable to legal challenges after issuing a standard. In general, government agencies must prove to a judge that a rule isn’t arbitrary or an abuse of discretion. OSHA, however, must show its rule is supported by “substantial evidence in the record considered as a whole”—a much higher standard.

All of this means addressing combustible dust is a mammoth task—and one that faces significant industry pushback.

The National Cotton Council told OSHA many of its members shouldn’t be included and challenged the accuracy of the agency’s list that included past cotton dust fires and explosions. The American Home Furnishings Alliance insisted in written comments that “no federal intervention in our industry is justified or required. The American Chemistry Council has taken a harder line, arguing that a new rule is entirely unnecessary. “We believe that the accidents that have occurred might have been prevented if current OSHA regulations and relevant combustible dust consensus standards had been followed and enforced,” the council wrote to the Center for Public Integrity.

In January 2003, the West Pharmaceutical Services plant in Kinston, North Carolina, exploded when a fine plastic powder ignited. Six workers were killed and dozens were injured. US Chemical Safety Board

In January 2003, the West Pharmaceutical Services plant in Kinston, North Carolina, exploded when a fine plastic powder ignited. Six workers were killed and dozens were injured. US Chemical Safety Board

Lessons from a previous dust fight

Many of the arguments over the dust rule echo those made 30 years ago during a tussle that led to a standard now widely considered a success story. In the late 1970s, a series of deadly explosions at grain elevators and similar facilities attracted national attention. OSHA announced in 1980 that it was considering a rule to regulate the handling of grain dust.

Large industry trade groups and small grain elevator operators objected vociferously. The National Grain and Feed Association called the rule “unwarranted” in comments to OSHA and said it “could have a substantial economic impact on the grain and feed industry without substantially improving the safety or health of workers.”

In 1987, OSHA issued the rule. In 2003, the agency found that, in the decade after it took effect, deaths in grain dust explosions dropped by 70 percent and injuries by 60 percent.

In 2010, the National Grain and Feed Association—the same group that had sued OSHA to try to block parts of the rule—noted this “unprecedented decline in explosions, injuries and fatalities at grain handling facilities” in comments submitted to OSHA. The association cited the “economic benefit of implementing the grain handling standard” and wrote, “We firmly believe that there is overwhelming evidence supporting the grain handling standard’s effectiveness in preventing fires and explosions and resulting injuries.”

Some in Congress want OSHA to act on combustible dust now. California Rep. George Miller and two other House Democrats have introduced a bill that would require the agency to issue an interim rule within a year. “The fact that workers are killed and injured in all too frequent, clearly preventable combustible dust explosions shows that Congress must act,” Miller said in a statement to the Center for Public Integrity.

In Georgia, the building Jamie Butler and his coworkers knew during their time at Imperial Sugar is long gone, consumed entirely by the inferno of February 2008. In its place is a modern packing facility company officials say stands as evidence of what they learned from the disaster. “If there is ever an explosion again—and that’s just not going to happen—it would never spread from building to building ever again,” Imperial Sugar health and safety official Kathleen Gonzalez said during a recent tour, pointing to a system designed to blanket the area with water and halt a fire in its tracks.

Sugar no longer enters the packing building on a conveyor belt—the location of the initial explosion in 2008. It is shot through pipes in pellets packed so densely that they shouldn’t be able to ignite. Sensors can detect the first signs of sparks in the pipes, then automatically isolate the area and flood it with a neutralizing solution.

Near work areas, vacuums take spilled dust to a vessel outside the building—a contrast from the company’s previous practice of using compressed air to clean dust, which blew it onto ledges and rafters where it eventually was shaken loose, fueling explosions. A sign reminds workers, “Your job is not complete until your work area is CLEAN.”

The company has told OSHA of its “strong support” for a combustible dust rule. “We believe that there is still a low level of knowledge of the extent of hazards of combustible dust in industry,” the company wrote OSHA.

A father’s memory

Chris Sherburne hasn’t given up on some of the plans she and Wiley made. They dreamed of building a new house on their land to replace their double-wide, and in December 2010—about a month before his death—they’d decided to start the following spring.

Chris stuck to the plan, functioning as her own general contractor. “I decided to just build it and see what happens,” she told us. Last December, Chris and her son moved into their new house. No pictures of Wiley adorn the walls or mantelpieces. “It’s easier for us not to have stuff in plain view,” Chris said. When Wiley’s body was cremated, at first the ashes sat on Chris’ bedroom dresser. “After a few days,” she recalled, “I said, ‘Wiley I can’t look at you every day; I can’t do this.’ He’s in the closet now.”

As their son approached driving age, the plan was for Wiley to help him find a clunker and fix it up. Instead, he now drives his father’s souped-up Dodge Ram 2500. “Every now and then, when I see it coming up the driveway,” Chris said, “for a split second I still think it’s Wiley.”