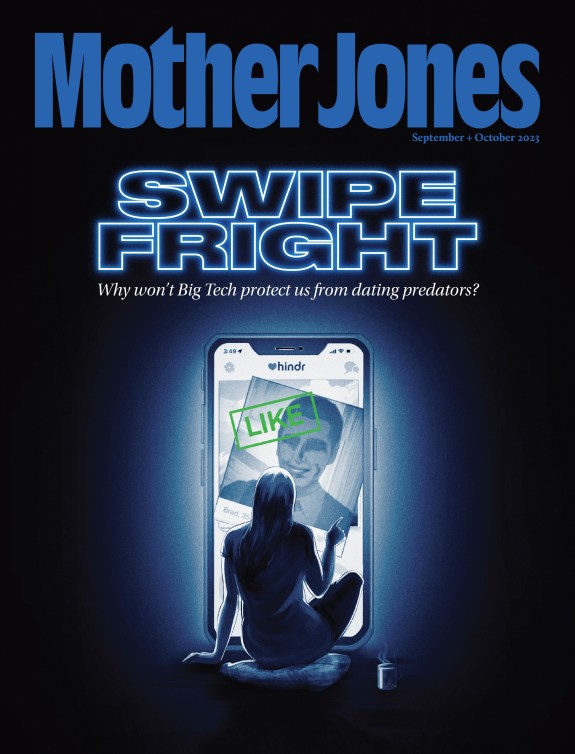

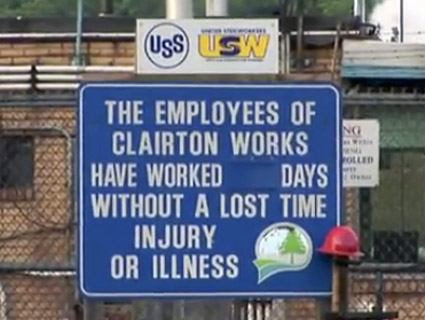

A safety sign outside the US Steel complex in Clairton, Pennsylvania, where Nick Revetta was killed in September 2009Center for Public Integrity

Update, 6/7/12: Two weeks after this story ran, the Occupational Safety and Health Administration announced that it has pared its inspection goal for the year. The revision was made primarily because the agency has been conducting “more complex, time consuming” inspections this year, an agency spokesman wrote in an email.

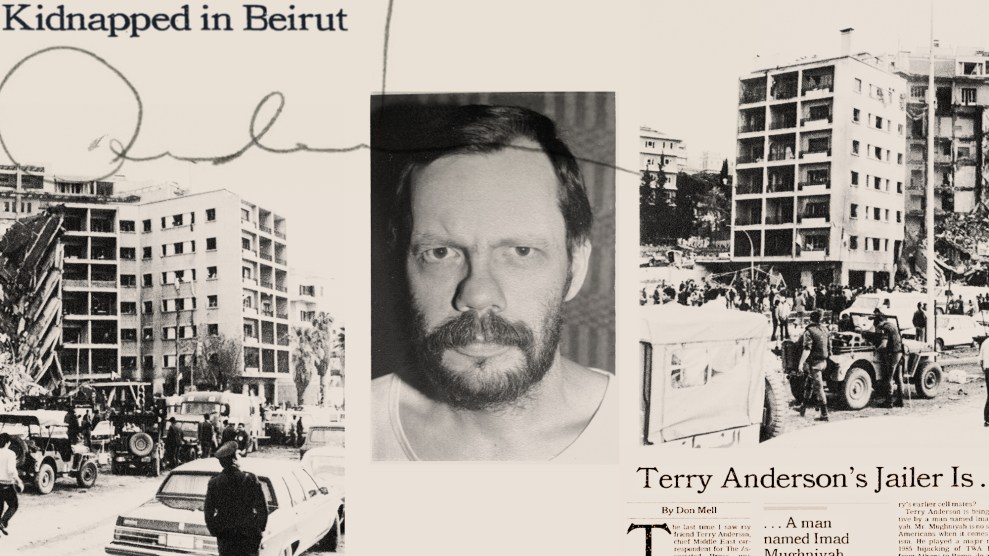

Early on the morning of September 3, 2009, Nicholas Adrian Revetta left the Pittsburgh, Pennsylvania, suburb of Pleasant Hills and drove 15 minutes to a job at US Steel’s Clairton Plant, a soot-blackened industrial complex on the Monongahela River. He never returned home.

Revetta was working as a laborer for a US Steel contractor that had employed his father, at the same plant that employed his brother. Shortly before 11:30 a.m., gas leaking from a line in the plant’s Chemicals and Energy Division found an ignition source and exploded, propelling him backward into a steel column and inflicting a fatal blow to his head. Thirty-two years old, he left behind a wife and two young children.

Nick Revetta’s death did not make national headlines. No hearings were held into the accident that killed him. No one was fired or sent to jail.

Under the Occupational Safety and Health Act of 1970, American workers are entitled to “safe and healthful” conditions. Revetta’s death and the events that followed lay bare the law’s limitations, showing how safety can yield to speed, how fatal accidents can have few consequences for employers, and how federal investigations can be cut short by what some call a de facto quota system.

In the Revetta case, the Department of Labor’s Occupational Safety and Health Administration (OSHA) failed to issue even a minor citation to US Steel, the world’s 12th-largest steelmaker and an economic leviathan in western Pennsylvania. The company paid no fine, although current and former workers say that its contractors— including Revetta’s employer—faced intense pressure to finish their work.

OSHA did look into Revetta’s death, as required by law. A safety inspector from the agency’s Pittsburgh office spent more than two months on the case, working tirelessly to find the cause of the explosion. Yet emails obtained by the Center for Public Integrity show that his requests for help went unanswered, and he was pulled off the investigation by a supervisor striving to meet inspection goals. “My problem is at what point do we give up quality for quantity,” inspector Michael Laughlin wrote in an appeal to a higher-ranking OSHA official in Philadelphia in November 2009. “I need some guidance because I’m torn and my spirit is broken because of the need to complete this case to the best of my ability.” The official advised Laughlin to “relax” and use the weekend to “go out and hit some [golf] balls!”

In the end, OSHA penalized an insulation contractor that had been working in the area of the explosion. The contractor paid $10,763 in fines unrelated to the blast and was not implicated in Revetta’s death. (The typical OSHA fine for an on-the-job death is less than $8,000; see sidebar.)

“The OSHA investigation that was done missed the point,” says John Gismondi, a lawyer who represents Nick Revetta’s wife, Maureen, in a lawsuit against US Steel. “It wasn’t the right type of investigation. They spent all their time on penny-ante stuff. How do you have a situation where all the pipes are owned or maintained by US Steel, you have an explosion, a guy is killed and you have no violation? How is that possible?”

“I’m upset with US Steel,” Maureen Revetta says, “but I think I’m angrier with OSHA. They’re the government agency that’s supposed to keep people safe…It just seemed like they purposely didn’t want to fine US Steel.”

In a written statement to the Center for Public Integrity, OSHA said it conducted a “thorough investigation” of Nick Revetta’s death. “It was determined [that] there was insufficient factual evidence that could support the issuance of citations specifically related to the root cause of the incident.”

David Michaels, assistant secretary of labor for occupational safety and health, would not talk about the Revetta case; nor would Robert Szymanski, the head of OSHA’s Pittsburgh Area Office. Edward Selker, the now-retired OSHA deputy regional administrator who urged inspector Laughlin to go hit golf balls, did not return calls to his home. A US Steel spokeswoman declined to comment. In a court filing, the company has denied any negligence in the case.

The silence has shaken Revetta’s former coworkers. “It just hasn’t gone away,” says John Straub, a US Steel employee who has worked in Clairton since 1979. “Nobody has really explained to us exactly what happened. They tell us they don’t know what the ignition source was. I was working in that same area a couple of weeks before the explosion. I look back and say, ‘That could have been me.'”

“These deaths take place behind closed doors.”

More than 4,500 American workers are killed on the job annually. There were 4,690 workplace deaths in 2010, a 3 percent increase from 2009. (A decade earlier, the annual toll exceeded 6,000. The soft economy, the Bureau of Labor Statistics notes, has led to fewer workers and less work in high-risk industries such as construction.) The US workplace fatality rate remains roughly six times that of the United Kingdom, which has stricter safety rules.

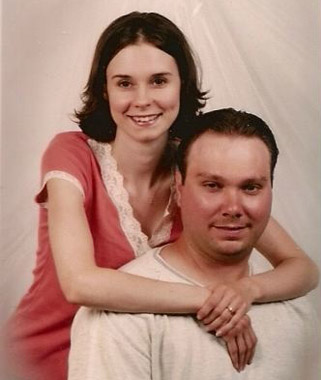

Nick Revetta (right) on his wedding day, with his older brother Patrick Courtesy of Patrick Revetta

Nick Revetta (right) on his wedding day, with his older brother Patrick Courtesy of Patrick Revetta

Combine the victims of traumatic injuries with the estimated 50,000 people who die annually of work-related diseases, and it’s as if a fully loaded Boeing 737-700 crashed every day. “These deaths take place behind closed doors,” says Michael Silverstein, the recently retired head of Washington state’s workplace safety agency. “They occur one or two at a time, on private property. There’s an invisibility element.”

It would take the perpetually short-staffed OSHA more than 130 years to inspect every workplace in the United States. Managers and their underlings must strike a balance between meeting “performance goals” set in Washington and conducting comprehensive inspections when deaths occur. A target of 42,250 inspections nationwide was established for fiscal year 2012, up 5.6 percent from the previous year’s goal. The number of federal inspectors, meanwhile, has stayed mostly flat; there were 1,118 in February 2012.

In a statement, OSHA said it “does not set strict inspection quotas. The Agency does, however, set inspection goals—and they are just goals—in order to monitor and manage our activities. We do not believe that these inspection goals preclude the Agency from doing a thorough inspection.”

Others aren’t so sure. “They called them goals, but you were definitely expected to make your numbers—that was the term of art,” says David DiTommaso, a former OSHA area director in Montana. “If you didn’t, you had to have a reason and you would be judged on it.”

In August 2011, with the federal fiscal year nearing a close, an unidentified safety supervisor in the OSHA regional office covering Pennsylvania, Delaware, Maryland, Virginia, West Virginia, and Washington, DC, urged inspectors to step up their pace and not get bogged down in the minutiae of complex cases, including those involving deaths and serious injuries. “As per our calculations this morning, we need an average of 14 inspections opened per week,” wrote the supervisor, whose name was removed from an email obtained by the Center for Public Integrity.

The supervisor went on: “Essentially, do what you gotta do to stay gainfully employed. It’s great to be caught up, but we only have a short window to open enough inspections to make all of our goals. I suppose you could say, ‘it’s not my problem’ but I can’t guarantee there wouldn’t be a ton of heat coming down from the RO [regional office] on any office that falls short. We are going to be getting a new RA [regional administrator] soon and being perceived as ‘slackers’ is not a good first impression. I know how difficult all of the accidents/fatalities/sig [significant] cases have been on everyone but unfortunately that won’t likely be taken into consideration when the clock strikes October”—the beginning of the new fiscal year.

Other OSHA emails obtained under the Freedom of Information Act reveal the numbers-driven pressures that existed in Pittsburgh after Nick Revetta’s death. In a message to then-deputy regional administrator Selker two months after the explosion that killed Revetta, inspector Laughlin acknowledged that “goals must be met” but said the case was “clearly not done.” His bosses nonetheless directed him to end the investigation. (Laughlin died in January after being struck by a car.)

A chart dated two days after Revetta’s death shows that OSHA’s Pittsburgh Area Office and the others in its region were easily surpassing their counterparts in the numbers game. With the fiscal year coming to an end, the region was ahead of its goal by 245 inspections. In an email four days later, Selker complimented Szymanski and other managers in Pittsburgh for the “very encouraging and impressive inspection stats…We can hit the ground running and get off to a good start in the first quarter instead of playing catch-up. If we can hold our own in the first quarter, it will make the rest of the year much less tense.”

Maureen and Nick Revetta Courtesy of Maureen Revetta

Maureen and Nick Revetta Courtesy of Maureen Revetta

“Daddy got hurt at work and he’s never coming home.”

Nick Revetta’s older brother, Patrick, is tall and solidly built, with grey stubble. Forty years old, he lives 11 miles from Clairton but has tried to avoid the place since the accident. He made an exception one bitterly cold day in January 2011. After pointing out the stadium where he played quarterback for the Clairton High School Bears, he drove past a string of deserted businesses on his way to US Steel’s hulking Clairton Plant.

Clairton, a city of 6,800 about 15 miles south of Pittsburgh, has seen better days. In 1980, US Steel employed nearly 5,000 at its complex, where coal is superheated in ovens and turned into coke, a key ingredient in steel. Though the plant remains a major employer, its staffing has dropped by three-quarters, not counting contract workers. Almost one-quarter of the city’s residents and nearly half of its children live in poverty.

The Revetta brothers and their sister, Kathy, grew up in Clairton the 1970s and ’80s. “This place was booming,” Patrick recalls. Stocky and stoic, Nick was the “spitting image” of his father Adrian, who worked for Power Piping Co., a construction and fabrication contractor. “They walked alike. They were built the same way—like bulls, basically,” Patrick says. Adrian got Nick a job at Power Piping; Nick would work there for 11 years.

Nick and Patrick grew exceptionally close after their mother, Patricia, died of cancer in 1991. “He was like a son to me,” Patrick says. “He drank his first beer with me at my college. I took him everywhere. I raised him.”

Nick met Maureen Mulligan in 1994, when they were 17, and they married nine years later. Their son Nick was born in 2005, their daughter Gianna in 2008. The children’s names were tattooed on their father’s right arm, along with the word Italia, a nod to his heritage.

Maureen, a 34-year-old special education and speech teacher, struggles to raise the children without their father. Six-year-old Nick craves male attention. “When [the accident] happened, he was 4½,” she says. “I don’t think he knew people died. I said, ‘Daddy got hurt at work and he’s never coming home.'”

The Clairton Plant is the largest operation of its kind in the country, with 12 clusters of coke ovens, known as batteries, which produce 4.7 million tons of the carbon-rich fuel annually. At the depth of the recession, in early 2009, coke prices were depressed and activity in Clairton was sluggish. As prices began to rebound that year, “there was a mad rush to get everything up and running again,” Patrick says.

Nick was caught in that rush. Power Piping was brought in to help refurbish three gas processing equipment. “You could see it every day,” says Patrick, a US Steel employee whose job at the time was to help control emissions from the coke oven batteries. “There was just too much pressure. They had to have that production, man. Nick, he kept telling me they were shortcutting stuff, putting pressure on them to hurry up and get the job finished. I said, ‘Just watch your ass.'”

OSHA inspector Laughlin’s voluminous notes reflect the frenetic work environment for US Steel contractors such as Power Piping. “They were pushing the manpower…US Steel pushing…pushing people,” Laughlin wrote while transcribing one worker interview.

The winter before he was killed, Nick logged 60 days straight at the Clairton Plant. “He was very proud of his job, proud of providing for his family,” Maureen says. “He never complained about working.” Subdued among strangers, animated among friends, Nick had few hobbies outside his family time. “I never really worried about his safety,” Maureen says. “Then, one morning about two weeks before he died, he said, ‘I don’t think you know what a dangerous place I work at.'”

Around the same time, Patrick recalls, Nick complained that there were gas “leaks all over the place” in a part of the plant’s Chemicals and Energy Division known as the No. 2 control room. “I always knew somebody would get killed inside that place,” Patrick says, “but I never thought in a million years it would be my baby brother.”

US Steel’s Clairton Works Sean_Marshall/Flickr

US Steel’s Clairton Works Sean_Marshall/Flickr

The explosion

Four days before Labor Day 2009, Nick and a coworker were given a routine assignment. They were to repair concrete pillars supporting the dormant B Cold Box, a pipe-filled structure the size of a storage pod in the No. 2 control room. The box is part of a cryogenic process used to separate “light oil” containing benzene, xylene, and toluene from coke-oven gas.

Nick was standing near the box, getting ready to mix grout, when, at 11:26 a.m., an explosion sent him hurtling backward into a column. He appears to have died instantly. A foreman at the plant later told OSHA inspector Laughlin that it looked like Nick had been buried in a snow drift, the “snow” being piles of white, fluffy insulation blown from the B Cold Box.

At the moment of the blast, Patrick was coming off his shift at the plant’s B Battery, maybe 100 yards away. “I heard a loud arcing noise,” he recalls. “I turned in that direction and saw the flash and heard the explosion.” He called Nick three times on his cellphone but got no answer.

Patrick ran to the lunch trailer and encountered Nick’s boss, who said Nick was unaccounted for. Then he saw his brother being carried out on a stretcher. Patrick’s chest grew tight, his breathing labored. He thought he was having a heart attack and was taken by ambulance to the plant clinic.

Eventually, a worker who’d found Nick told Patrick his brother was dead. Patrick began cursing everyone within earshot, then went straight to Jefferson Regional Medical Center, where Nick had been taken. He asked to see his brother’s clothing, which was “soaking wet. You could smell the benzene.” He saw no signs of trauma: “There wasn’t a burn mark on him.”

Although an autopsy would establish the cause of death as blunt-force trauma to the head and trunk, Maureen also detected no evidence of serious injury when she saw Nick’s body that afternoon. “He looked perfect,” she says, “except for a little red line on his nose.”

Investigating the accident

Mike Laughlin was dispatched to the Clairton plant about two and a half hours after the explosion. A heavyset Army veteran with a thick grey mustache, Laughlin had investigated dozens of fatal accidents since joining OSHA in 1990. Rose Bezy, vice president of United Steelworkers Local 1557, which represents about 1,200 US Steel workers in Clairton, joined Laughlin as he picked his way through the debris around the demolished B Cold Box. “The guy was relentless,” Bezy says. “He was all over the place.”

US Steel officials followed Laughlin as he worked. “Whenever he would take a picture,” Bezy says, “there would be a US Steel guy with a camera, taking the same picture.” Three well-dressed corporate security officials from Pittsburgh appeared at the plant several hours after the accident, Bezy says, and forbade Clairton managers from sitting in on interviews with lower-level employees, as would customarily occur. “It looked to me like US Steel’s own managers were intimidated,” she says.

Early in his investigation, Laughlin realized that he needed help navigating the complex federal rules detailing the steps companies must take to prevent catastrophic fires, explosions, and chemical releases. He kept pressing Pittsburgh area director Szymanski to pair him with someone who had expertise in this “process safety management” protocol. OSHA has several hundred inspectors nationwide with such specialized training, including two in Pittsburgh. These specialists can draw conclusions from mangled pipes and burned-out vessels—clues likely to be missed by generalists like Laughlin.

Laughlin made his initial request for help not quite two weeks after Revetta’s death. Former OSHA managers say the request should have been granted. “It doesn’t make a whole lot of sense that you have an explosion where one of your [inspectors] is asking for help and you don’t give it to him,” says Dave May, a former OSHA area director in New Hampshire who oversaw some 100 fatality investigations. “In a fatality you bend over backwards to get the help.”

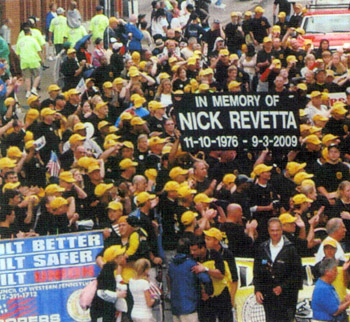

A Labor Day memorial parade for Nick Revetta in Pittsburgh four days after his death Courtesy of Patrick Revetta

A Labor Day memorial parade for Nick Revetta in Pittsburgh four days after his death Courtesy of Patrick Revetta

DiTommaso, the former Montana area director, says, “In a situation like [the Revetta accident], we would have got a team in there. You would call the regional administrator and say, ‘Look, I’ve got this type of case. Can we get some people who have heavy experience in that from somewhere around the country?’ You’ve got to make sure there’s not a continuing hazard.”

The precise cause of the explosion that killed Nick Revetta remains a mystery. Workers had been grinding and welding on the B Cold Box just prior to the blast, but none of the witnesses interviewed by Laughlin reported smelling gas. “No evacuation alarm ever went off,” a foreman told Laughlin, according to the inspector’s notes.

Another witness said he’d heard “a large gas escaping sound—definitely a pipe hissing—and [seen] a big ball of fire” near Quad 3, a trailer-sized structure, containing four cryogenic vessels, located close to the disabled B Cold Box. There had been an explosion in Quad 3 in 2005. No one was hurt, and US Steel blamed the event on lightning.

Gismondi, Maureen Revetta’s lawyer, says US Steel’s own investigation, which has not been made public, concluded that “there was a gas leak inside [Quad 3] and oxygen got in.” This suggests that two of the three ingredients required for an explosion—flammable gas and oxygen—were present. All that was needed was an ignition source—something as simple as static electricity. US Steel declined to comment.

Ten months after Nick Revetta’s death, another explosion rocked the Clairton Plant, injuring 17 workers. OSHA blamed the accident on a contractor shortcut that had been approved by US Steel, an allegation the company is contesting.

Near-misses

John Straub, a senior operating technician with US Steel, was at home the morning Nick Revetta died. He learned about the explosion from his wife, who’d seen a bulletin on TV. “I said, ‘I know exactly where it was.'” A casual acquaintance of the Revetta brothers, Straub had worked in the area of the blast and had been troubled by what he described as sloppy “hot work” procedures designed to contain sparks from welding and burning.

The job to which Nick Revetta had been assigned—the rebuilding of the B Cold Box—was, in Straub’s view, being done without proper enclosures to segregate potential sources of ignition. It was part of a disturbing trend he’d observed: Precautions that would have been taken five years earlier were deemed too expensive and time-consuming. “In the old days, responsibility for safety was shared by the contractor and US Steel,” Straub says. “Now it’s just somebody else working. You don’t look at [a contract employee] like it’s your son or your daughter or your dad working, which you should.”

Straub filed a 10-page, handwritten complaint with OSHA’s Pittsburgh office in January 2010, alleging that US Steel had violated the process safety management standard. Straub claimed that several “near-misses” in the No. 2 control room before Revetta’s death hadn’t been investigated. Six months later, OSHA cited US Steel for five “serious” violations related to Straub’s complaint and proposed a $32,400 fine. The company settled and paid $19,800.

Not long after Straub filed his complaint, Maureen Revetta learned that OSHA’s investigation into her husband’s death had been closed, with no citations issued to US Steel. She and Gismondi had two unsatisfying meetings with OSHA officials in the summer of 2010. In the first, “One guy said, ‘We don’t have enough resources,'” Maureen recalls. “I wouldn’t tell parents that I don’t have enough resources to teach their kids. I have to figure it out. That’s no excuse.” In the second meeting, which included then-deputy regional administrator Selker, Gismondi produced inspector Laughlin’s written request for help and asked why it hadn’t been honored. “They were flustered,” the lawyer says.

In October 2010, Gismondi approached Assistant Secretary of Labor for Occupational Safety and Health David Michaels at a conference in Pittsburgh and hand-delivered a letter. “Mrs. Revetta and I have strong concerns that the OSHA investigation into this accident was not as thorough and complete as it should have been,” it read. A month later, Michaels replied that the process safety investigation sought by Laughlin “would not likely have determined the root or underlying causes of the incident that killed Mr. Revetta” and that Straub’s complaint already had resulted in citations that would discourage “unsafe practices at the Clairton Plant.”

In her own letter to Michaels, the United Steelworkers’ Bezy observed that it took an expert—Pittsburgh-based OSHA inspector Jan Oleszewski—to document the violations Straub had alleged. Oleszewski or someone like him should have been assigned to the Revetta investigation, Bezy argued. “I fear that [US Steel] will continue to injure and kill our employees and those who contract to work in our plant,” she wrote. “They seem to be above the law in matters of Health and Safety.”

Indeed, one week before Oleszewski cited US Steel for violations stemming from the Straub complaint, the Clairton Plant blew up again. It was not even a year after Nick Revetta was killed.

“You thought someone was dying.”

On the morning of July 14, 2010, Denny Lentz, a steamfitter with Power Piping, was helping a coworker install a flat piece of steel between flanges on a 30-inch coke oven gas line in the Clairton Plant’s B Battery. The “blank” was supposed to block the flow of gas while the men repaired a leaking valve. Something went wrong: Lentz, outfitted in a self-contained breathing apparatus, could hear and feel escaping gas. “It was blowing the coal dust off the ceiling,” he says. “Once you got gas blowing everywhere, it’s gonna find a spark.”

One of many shuttered storefronts in the steel town of Clairton, Pennsylvania charltonlidu/Flickr

One of many shuttered storefronts in the steel town of Clairton, Pennsylvania charltonlidu/Flickr

Lentz says that a gas alarm went off several times, but a US Steel supervisor silenced it each time. “I was thinking, ‘I gotta hurry,'” Lentz says. He was rushing to tighten the bolts on the flanges when a wall of flame “came right at me and blew me over.” He remembers picking himself up off the ground and hearing screams: “You thought someone was dying.” The fire peeled the skin off his hands; his ears and the back of his head were burned as well. Others, including the US Steel supervisor, were burned more severely.

OSHA said the procedure approved by US Steel—allowing coke oven gas to keep flowing through the line rather than shutting it off and purging it with nitrogen—invited disaster. The agency cited the company for 12 alleged violations and proposed a $143,500 fine. One violation was classified as “willful,” suggesting OSHA believes the steelmaker either disregarded or was “plainly indifferent” to safety rules. US Steel is appealing. Lentz and other workers hurt in the accident are suing the company.

Could a more complete OSHA probe and sanctions in the Revetta case have prevented the second blast in Clairton? Celeste Monforton, a former OSHA analyst who lectures at the George Washington University School of Public Health, says that Revetta’s death should have prompted a broader investigation that might have identified other hazards. “OSHA should have used that as an opportunity to look at the entire operation rather than just limiting its inspection to the area where the fatality occurred,” Monforton says. “To me, it’s just inexplicable that they didn’t do it. People can say all they want about OSHA’s lack of resources, but they had the tools to go in.”

OSHA’s Field Operations Manual gives local managers considerable latitude to determine the scope of fatality investigations. May, the agency’s former New Hampshire area director, says, “If the place is a mess and it’s had a fatality, it’s not atypical that you jump in and say, ‘We need to do the whole place.'”

Still waiting for answers

Patrick Revetta has lost 30 pounds since Nick was killed. “He’s not the same person I’ve known for 10 years,” says his wife, Kathy. “He holds everything in. He sits there in a daze.” Still a US Steel employee, Patrick is out on medical leave for post-traumatic stress disorder.

“I got a lot of bitterness in my heart over this, and I don’t think it’s ever going to go away,” he says. “How is it that somebody gets killed, OSHA finds nothing, and they send guys back in and go back to full production? I believe OSHA turned their head to it.”

His father, Adrian, died of complications from diabetes 13 months before Nick was killed. Adrian would not have allowed the cause of the 2009 explosion to remain undetermined, Patrick says. “If my dad were still alive, there would have been an answer.”

On a Saturday in January last year, he drove to the snow-covered Finleyville Cemetery, where his brother, parents, and grandfather are buried, and parked his truck next to the family plots. A small Pittsburgh Penguins flag fluttered next to Nick’s headstone; following the hockey team had been one of his passions.

On his way down the hill a few minutes later, Patrick gave his horn two taps. Goodbye, little brother.