Aruna, 19, recalls that her bosses at the mill “said that we would get less work if we slept with them.”All photos by Redux

ARUNA, A 19-YEAR-OLD NURSE I met in the southern Indian state of Tamil Nadu, is a lot like some of my friends in Washington, DC—bright, single, self-assured, loves her job. She speaks quickly and eloquently, not stopping to drink her tea and hardly ever even pausing to breathe. When I first meet her in Coimbatore, a city known for its textile industry, she is on her lunch break, wearing her freshly starched white uniform and a traditional red bindi dot on her forehead.

If Aruna were one of my friends in DC, no one would be asking her why she isn’t hitched yet. But in Aruna’s home village, if you haven’t secured a husband by your early 20s, you’re in for a hard ride. “In India, a woman is auspicious because she is married,” says Srimati Basu, an associate professor at the University of Kentucky who is an expert on the status of women in India. “Lack of marriage is horrible for the person, the family, and the community.”

In order to get married, Tamil village girls like Aruna need at least three gold British sovereigns—bullion is the preferred currency for dowries—the equivalent of about $1,200. Together, Aruna’s parents make a little less than $400 a year.

As a child, Aruna dreamed of going to college. But by the time she was 15, when her government-subsidized schooling ended, she understood that she was too poor. Then, a stranger promised to change her life. He offered her a job at a textile factory that has supplied companies including, until recently, UK-based maternity wear maker Mothercare. Her pay would be about $105 a month—enough for food for her family, her further education, and most importantly, the chance to build a dowry.

When Aruna arrived at the factory, about 40 miles from her home, she found a vast facility where close to 1,000 girls, many in their teens, lived 10 or 15 to a room. From 8 a.m. till 10 p.m. every day, including weekends, she fed and monitored rusty machines that spun raw cotton into yarn. Her bosses often woke her in the middle of the night because, she recalls, there was “always some sort of work, 24 hours a day.” Aruna made just a quarter of the $105 a month she was promised, about $0.84 a day.

Aruna shows me a scar on her hand, more than an inch long, where a machine cut her. She often saw girls faint from standing for too long. One had her hair ripped out when it got caught in a machine. Others were molested by their supervisors. “They said we would get less work if we slept with them,” Aruna says. Sometimes girls would disappear, and everyone would speculate whether they’d died or escaped. Still, she needed the money, so she worked there for two years. After she left, a garment workers advocacy organization called Care-T helped her get her current job at the hospital, where she is slowly saving up for a dowry. When I ask if she still has her sights set on college, Aruna shakes her head and tears fill her eyes. But almost instantly, she wipes them away. There’s no point thinking about that, since she already has a steady income. “I like my job at the hospital now,” she says. Most of her friends are still working at the factory. (The names of Aruna and other former factory workers have been changed to protect them from retaliation.)

In Tamil Nadu, many people know a girl like Aruna, someone who has been lured to work in the garment factories with the promise of earning a dowry. The scheme is so common that it even has a name: sumangali, the Tamil word for “happily married woman.” A 2011 report by the Dutch watchdog groups Centre for Research on Multinational Corporations and India Committee of the Netherlands found that sumangali factories employed an estimated 120,000 workers, some as young as 13, and supplied dozens of international companies, including Gap (which denied the allegation), H&M, American Eagle Outfitters, and Tommy Hilfiger.

Last April’s building collapse in Bangladesh’s Rana Plaza, which killed more than 1,000, briefly drew attention to the plight of garment workers. India is an even larger global player than Bangladesh: It’s the third-largest textile and garment exporter in the world (after China and the European Union), with about $29 billion in 2012 sales. Between June 2012 and June 2013, the United States imported about $2.2 billion worth of cotton clothing from India, and that number is expected to grow as India ramps up its textile industry.

In the garment industry the world over, it is common for workers to be locked into exploitative conditions until they fulfill contracts. But in India, the dowry tradition—which persists even though it’s officially illegal—makes teenage girls especially vulnerable to these schemes. In part because of this, India has comparatively strong child labor regulations: It’s illegal for children younger than 14 to work in factories there, and all workers must be paid double for overtime. Enforcing those laws, however, is another matter. Factories go to great lengths to cover up illegal practices. (Aruna recalls that when inspectors would come—she didn’t know whether they were government or company auditors—factory supervisors would shove the younger girls into a special wing. If they were found, they were told to say that they were 18.)

And workers themselves hardly ever report abuse, in part because many come from lower castes, including the dalit, or untouchables. “People don’t take up these issues with factory management because they are afraid of losing income and afraid of possible retaliation because they are in a vulnerable position in society,” says Heather White, a fellow at Harvard’s center for ethics who has researched global clothing supply chains. In her interviews with factory workers, she says she heard about “numerous cases of sexual harassment, which normally in the factory worker context means rape.”

In 2012, the workers’ rights group Fair Labor Association examined the cases of 78 sumangali workers who, at dozens of factories, had committed to work for three years. Of the 34 girls who did not complete their contracts, 4 died from accident or illness, 11 were forced to leave due to health problems, 17 were taken home by their parents, and 2 left on their own. Twenty were still working at the time of the FLA interviews, and 24 had completed their contracts. Several other NGOs confirmed that it’s very common for girls to not complete their contracts and that on-the-job accidents and even deaths are not at all unusual.

Although some of the workers told the interviewers that they had been sexually harassed by supervisors, the report’s authors noted that girls rarely report such incidents because doing so could affect their marriage prospects—and is unlikely to bring results in court, anyway. While reported cases of rape in India have been on the rise, the conviction rate—less than 27 percent—has dipped over the last decade, and victims who go to the police have been known to be raped by them as well.

Despite the growing evidence that abuse is common in sumangali factories, most Western companies have not yet eliminated the practice from their supply chains. A major American trade group, the United States Association of Importers of Textiles and Apparel (USA-ITA), has pressured suppliers in other parts of the world to clean up bad labor practices; it recently convinced Bangladesh to pass a binding five-year plan to increase the number of inspections and improve worker safety training. Yet when I asked Samantha Sault, the group’s spokeswoman, about sumangali factories, she said, “We have not been aware of the labor practices that you describe.” She added that it sounded “disturbing.”

SINNATHAMBY PRITHIVIRAJ is a gruff, heavyset man who heads Care-T, the group that helped Aruna find her nursing job. For a decade he has been working with sumangali girls from his office in Coimbatore; he has helped 1,600 of them find work after returning from stints in the factories. If I want to see where the girls come from, he says, I need to go to Aruna’s home village, where he’s seen an uptick in recruitment recently. He says I should look for “the girls with alcoholic and missing fathers,” because “that’s where the recruiters are looking.”

We set out early the next morning, driving south through heavy traffic past unfinished strip malls and gated textile factories. Getting to the village—a tea-growing area of 71,000 residents, with settlements clustered around 56 different estates—requires a fearless driver managing a rickety stick shift on tight hairpin turns and a healthy tolerance for the 2,000-foot elevation gain. We repeatedly stop the car to let our guide vomit. When we arrive, we see the tea blooming in neon-green tufts straight out of Dr. Seuss. Most of the tea workers are from the lower castes and make about $3 per day; it costs a month’s salary just to outfit a child with books and a uniform for school. “We can’t give all our children food and schooling, so we sacrifice one child’s future for the others,” one mother tells me. “In these jobs, girls are preferred, so girls go.”

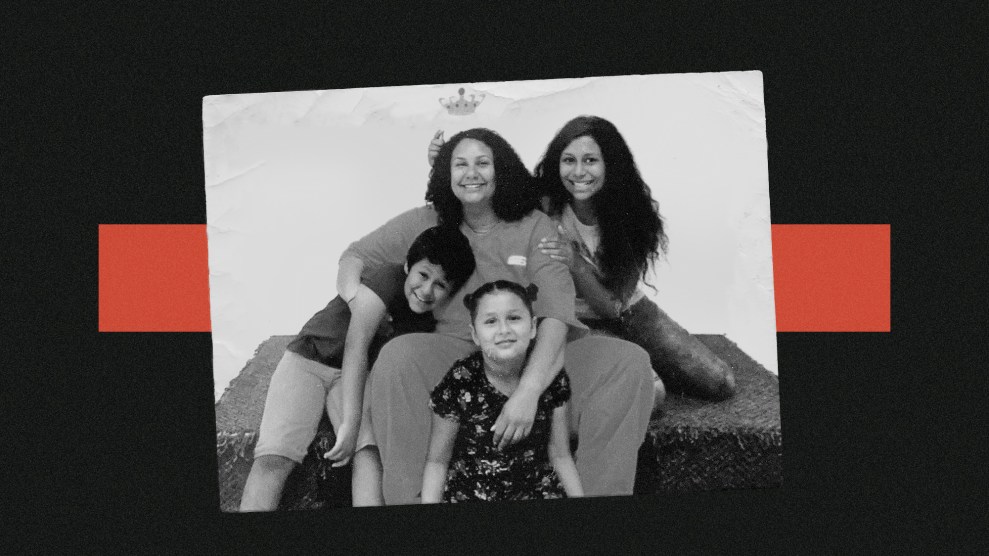

When I arrive at Care-T’s office in the village, I am greeted by Julia Jayrosa, the organization’s 31-year-old coordinator, in a small room packed with a dozen women and their children. Jayrosa, who seems to have boundless energy and speaks so quickly that I have to beg her to slow down, makes it her business to know what’s happening in every house in the village. She tells me there are at least 800 girls from here working in sumangali arrangements right now. Agents are paid $34 to $50 for every worker they recruit to the mills, she says, showing me a bright pink poster that was distributed around the village in May. It promises that in the factories, girls will get part-time education, private bedrooms, and excellent pay. Jayrosa is afraid of the agents and fears that they might shut down her meager business: She provides space for several dozen former factory workers to use their stitching skills and sell their own garments in the village. Her main concern right now is raising enough money to get the women a bathroom, so they don’t have to keep going in the jungle.

I spend the day with Jayrosa, talking to the villagers who come in and out of the office. I meet five former sumangali girls, as well as three mothers and a father who sent their daughters to the factories. I talk to a woman who had a miscarriage at a factory because she had to stand so long in the heat, and another who tells me that sexual harassment was rampant in her factory, but “you have to be smart enough not to fall for their tricks.”

At dusk, I meet a girl named Selvi, whose family invites me to their home. At 20, Selvi looks no older than an American middle-schooler, and she weighs 85 pounds. She is shy, quiet, and doesn’t often make eye contact. She says she spent the last two years doing stitching for a factory. The recruiter promised her 250 rupees (about $4) per shift, but she says she made only 150 (about $2.50) plus overtime of 15 rupees per hour—even though the legal overtime requirement is twice her hourly pay, or 34 rupees per hour.

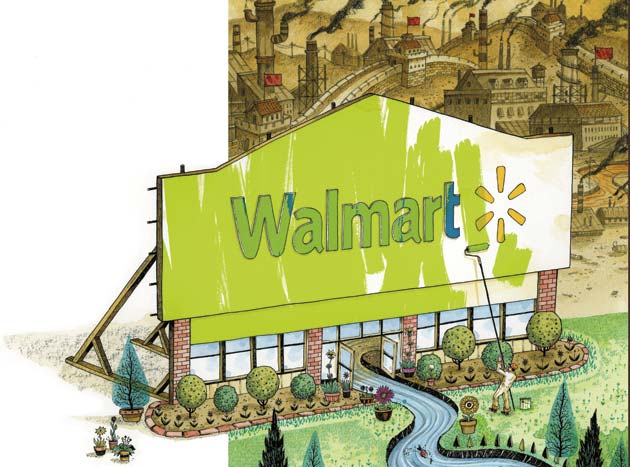

The company that owns the factory where Selvi worked has supplied clothing to Mothercare, Walmart, H&M, and the Children’s Place. H&M reports that it found no evidence of sumangali workers in its recent audits of three of the company’s factories. In 2011, however, the workers’ rights group Anti-Slavery International found that the company that runs the factory where Selvi worked was paying workers less than half of what they were promised, sometimes withholding a portion of pay until the workers completed their contracts, monitoring the girls’ phone calls, and refusing to let parents visit their children. (The company denies these allegations, and Selvi was allowed to collect her pay and take leave from the factory in March because of problems with her thyroid. She plans to go back to work as soon as she gets better.)

As night approaches, a village official hurriedly tells us we need to get back to the main estate. “The mist is coming,” he warns. “The men come home drinking at this time. They are rowdy. Also, the tigers descend.” I want to ask him what’s more dangerous, the drunk men or the tigers, but he’s one step ahead of me: “Elephants. Yesterday this time, there was one right here.” I exclaim, “It’s like a jungle!” My driver looks like he wants to strangle me. “It’s not like a jungle. It is a jungle,” he snaps, slamming the door.

BACK AT MY HOTEL that night, I rummage through my suitcase, looking for the least smelly thing to wear the next day. I find a brown T-shirt I picked up from Urban Outfitters. With a touch of dread, I search the seams for the manufacturer’s label. It says “Made in Indonesia,” so I can be sure it wasn’t made by one of the girls I’ve just interviewed. But even if it had been made in India, if I had called the company and tried to figure out which mill it came from, it would be almost impossible to determine whether sumangali workers were involved. Indian companies work hard to keep their labor practices quiet, hiding workers from inspectors and threatening NGOs that expose their practices. “This is not the USA or the EU,” says Care-T’s Prithiviraj. “There is no physical safety for us and our staff.”

The next day, I see firsthand what he means. On the way back from the village, I tell my translator that I want to stop at a factory owned by KPR Mill Limited, a textile company that the Dutch NGOs found to employ sumangali workers in a 2012 report. KPR Mill denies the allegations and claims to have “done several improvements far ahead of the other industrial fraternity.” As recently as December 2012, Quantum Knits, a subsidiary of KPR Mill, exported tens of thousands of clothing items for Jerry Leigh, which sells to Disney, among many other Western brands (though it is impossible to know for sure whether clothes from the factory ever reached Disney, and Debbie Bernstein, a spokeswoman for Jerry Leigh, claims that her company recently stopped buying from Quantum Knits altogether).

I had already spoken to a mother who said that two of her daughters were recruited to KPR Mill’s spinning facility in a village near Coimbatore when they were 16 and 17. The agent promised that they would work mornings and go to school in the afternoons. Instead, the girls allegedly worked between 8 and 12 hours daily, plus overnight shifts. Care-T, which later helped the girls get counseling and job training, told me that the 16-year-old was badly injured by a machine belt that snapped and hit her eye; the company did not grant her any medical leave, instead forcing her to pay a quarter of her monthly salary for treatment. Care-T says that the girls tried to escape but were brought back to the mill and had their phone calls monitored until they were sent home for a holiday break. They never went back, and a KPR Mill spokesman says that the mother’s allegations are “far from reality.”

The spokesman tells my translator over the phone that I can’t visit the grounds unless I know someone who works there, so I decide to ask in person. As we dodge cows and scooters on a dusty road in the outskirts of Coimbatore, my Tamil translator begins to look worried. “This isn’t a good idea,” she says, smoothing the scarf of her shalwar kameez for the tenth or hundredth time. After an hour of U-turns and badgering bewildered locals for directions, we finally find the plant. And I begin to see why my translator is nervous: The building, a vast compound with tall, guarded gates, could be mistaken for a military base.

We pull up across the street and my photographer snaps some pictures. Within seconds, a man with a thick mustache arrives, knocking on our window. “What are you doing here?” he yells. “Delete that photo!” I apologize and offer to leave immediately—but then I realize that we can’t: At least two dozen men have run from the gates and are surrounding our car, putting their hands on the bumper. The man with the mustache, who appears to be the boss, is apoplectic. He says that he won’t let us leave if we don’t delete the pictures and demands a copy of our IDs. Members of the mob are yelling in Tamil, and my driver throws his hands off the steering wheel, warning us that if he touches the gas, they are likely to break the windows. “We sell to American and European companies!” the boss warns. “What gives you the right to think you can take photos here? Foreigners can’t take photos in Coimbatore!”

He lets us go after we apologize profusely and our driver gives him the address of the hotel we checked out of earlier that morning. The company, we later learn, sends representatives straight to the hotel; they end up calling us from the police station, threatening to have us jailed. An officer recommends that our photographer leave her hotel in Coimbatore because he’s concerned about her safety. That night, even though we are hundreds of miles away at a hotel in Chennai, I double-bolt the door and don’t sleep.

Later, the KPR Mill spokesman tells me over email that the factory only “recruits the workers from the age of 18” and provides “utmost care and safety” for its 10,000 employees, who may end their contracts whenever they see fit. When I ask why the boss wouldn’t let me see the factory, he says, “We would like to advise you that you do not do such photography to intimidate us.”

YOU WON’T FIND a Western clothing manufacturer that openly approves of sumangali labor, but cracking down on it is a different matter. That’s because textile supply chains are vast and mind-numbingly complex. The average Indian T-shirt begins in a cotton field in western states like Gujarat and Maharashtra, where fluffy, plum-size balls are harvested by workers who generally come from the lower castes. From there, the balls are shipped in trucks to warehouses and sold to spinning mills, where machines (like the kind that cut Aruna’s hand) process raw cotton bales into thread. Then workers weave the thread into strips, dye them, and send them to factories that do final processing.

Marijn Peepercamp, a researcher who contributed to the 2012 Dutch watchdog report, estimates that 80 percent of spinning mills in Tamil Nadu employ sumangali workers. She tells me that when US companies find out they’re supporting sumangali, they often increase inspections in garment factories—but not necessarily the mills, which can be located several villages away. Andrea Roos, a spokeswoman for H&M, told me that when inspectors find safety or labor problems at a garment factory, the company does three unannounced audits over the next 18 to 24 months. But of the spinning mills, she says, “We normally do not have direct contractual influence.”

Elizabeth Cline, the author of the 2012 book Overdressed: The Shockingly High Cost of Cheap Fashion, says that’s a cop-out. “Western brands call the shots, and these factories will meet whatever standards the major brands require to keep the work,” she tells me. Still, there are some hopeful signs. Last year, three NGOs partnered with KPR Mill to set up a hotline for workers to report problems to the NGOs. One anti-sumangali program called Social Awareness and Voluntary Education has been able to inspect wage slips and age certifications at some factories. SAVE director Aloysius (who, like many Tamils, goes by only one name) says he is pleased with the progress so far, but there is still more to do. “I am not saying that every issue is tackled by us,” he says. “But there is an opening.”

Indeed, some Western companies have taken measures to discourage their suppliers from using sumangali labor. Levi Strauss & Co. provides financial support to SAVE, while Gap helped establish the Tirupur Stakeholders Forum, which sets detailed ethical guidelines for factories. More than 80 companies, including Gap, H&M, and Walmart, have joined an industry group called the Ethical Trading Initiative, which works with NGOs to educate workers about recruiting schemes and is trying to reduce the sumangali contract terms from three years to six months. But Peter McAllister, the director of ETI, would not speak specifically about any of the Indian companies whose factories I investigated, nor their Western buyers, because the group is concerned about the delicate relationship it has with the companies. Care-T’s Prithiviraj has similar concerns; he doesn’t want contractors to drop Indian factories because, he says, then mills simply would work harder to hide sumangali workers and fire girls who desperately need the income.

In response to pressure from ETI and other labor groups, each of Tamil Nadu’s three key garment industry associations developed its own set of guidelines for recruiting women to work in textile factories, as well as a code of conduct for the hostels where the factory girls live. But in 2012, the Fair Labor Association determined that while many of the recommendations—giving employees actual wage slips, capping work at eight hours a day, and banning sexual harassment—were steps in the right direction, they didn’t include any instructions for enforcing these policies. And some of the new guidelines spoke volumes about the companies’ attitudes toward workers: The Tamil Nadu Spinning Mills Association, for example, suggested replacing ceiling fans with wall fans, since ceiling fans “give access for person to commit suicide by hanging.”

A FEW MONTHS after I return from India, I go out to drinks with some friends, one of whom is wearing a rad pair of black tights with stripes up the sides. When I ask her where they came from, she proudly tells me that they cost just $20 at H&M. I don’t push for details, because who am I to judge? I’m wearing a made-in-India Urban Outfitters shirt I bought before my trip. I looked at the label when I returned home, for the very first time. This is a thing I do now, even though it won’t tell me what I want to know: Somewhere down the supply chain, did Aruna or Selvi make parts of my shirt?

Or maybe it was made by Lakshmi, one of the oldest sumangali workers I met. At 25, she was a year older than me, all of 4-foot-10, and wearing a beautiful orange dress covered with flowers that she had embroidered herself. Beginning at age 16, she worked at a spinning mill for five years, in conditions she called “torture.” Supervisors offered her vacations in return for sex, and when she declined, she says they denied her lunch breaks. She was dyeing yarn with chemicals that burned her hands and gave her boils. Supervisors would only give girls gloves occasionally, deducting the cost from their pay. Her hands would go numb for days. After five years, she left with about $620—half of one month’s rent on my studio apartment—and crippling ulcers. She has since spent her wages on doctors’ bills, and there is nothing left for a dowry.

I interviewed her in her room, which was filled with embroidered blankets. It was night, and the stars were as numerous as they are in the big sky of Montana, where I grew up. Through the open windows we could hear a chorus of insects. We took a photograph together, sitting on her cot, and she put her arm around me and grinned. A calico cat jumped from the dirt floor onto the bed. For that second, we were just two young women—unmarried, drinking tea, tired from a long day. But after we stood up, I knew that I would soon get on a plane to Washington, DC, where stores selling cheap leopard-print pumps and skinny jeans line the streets and no one expects me to give my entire salary to my parents for a dowry. And Lakshmi would still be here in this room, knowing—as she told me right after the photo was taken—that “no man is going to marry me now.”

This story was completed with financial assistance from the Social Justice Reporting for a Global America Program, sponsored by the Ford Foundation and the International Center for Journalists.